Introduction

The past decade has seen an explosive rise in automated medical devices—robotic surgery arms, automatic drug delivery pumps, and intelligent imaging scanners are all gaining mainstream adoption. At the heart of these systems lies the gear motor, a compact yet powerful component that turns electrical signals into precise mechanical motion. For engineers tasked with upgrading legacy equipment or designing new devices, choosing the right gear motor is critical to performance, safety, and compliance. This guide walks through the fundamentals of gear motor selection, practical criteria for matching them to medical applications, and emerging trends that promise even greater efficiency in the near future.

Why Gear Motors Matter in Medical Automation

1. Compactness & Integration – Medical devices must fit into tight spaces—think surgical robots that slide into a 3‑inch corridor or insulin pumps that sit comfortably on the skin. Gear motors achieve high torque from small footprints, making them ideal where space is limited.

2. Reliability & Endurance – Patients count on life‑supporting equipment working flawlessly. Gear motors built with medical‑grade materials and robust gear trains can run for millions of cycles with minimal wear, meeting ISO 13485 and FDA reliability requirements.

3. Precision & Control – Precise positioning is essential for tasks such as needle placement or MRI gradient control. Gear motors deliver fine step resolution, low backlash, and high holding torque, enabling smooth, repeatable motion.

4. Energy Efficiency – Modern hospitals aim to reduce energy consumption. Gear motors with low slip and high gear ratio efficiency translate electronic power into mechanical work with fewer losses.

Types of Gear Motors Common in Medical Devices

| Gear Motor Type | Typical Use | Strengths | Considerations | |-----------------|-------------|-----------|----------------| | Planetary (Epicyclic) | Robotic joints, surgical tools | High torque density, small size | Requires controlled speed to prevent wear | | Worm Gear | Slow‑speed high‑torque valves, drug pumps | Excellent speed reduction, non‑backdrivable | More backlash, lower efficiency | | Spur Gear | Conveyor drives in clean rooms | Simple, cost‑effective | Higher peak loads, more vibration |

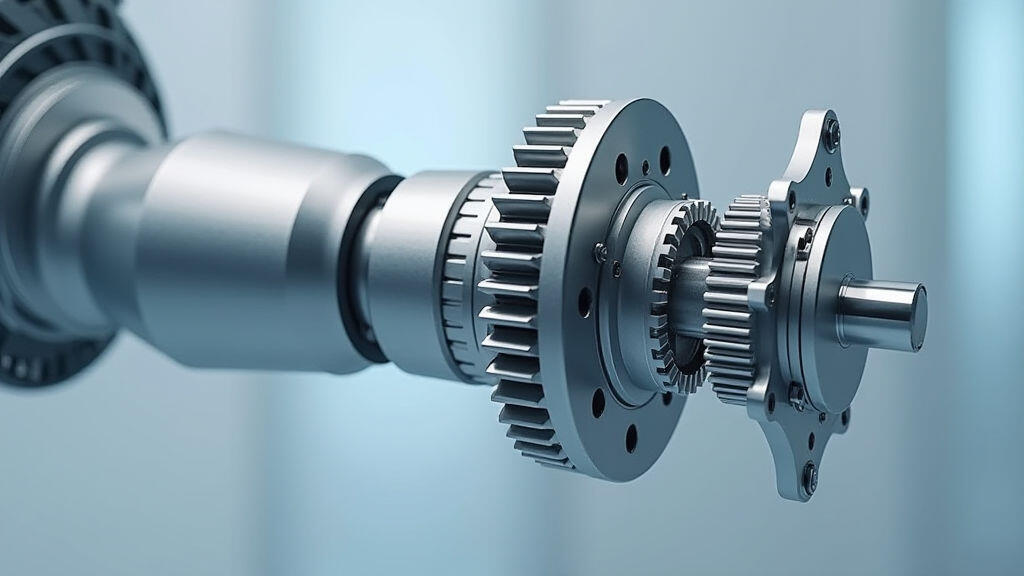

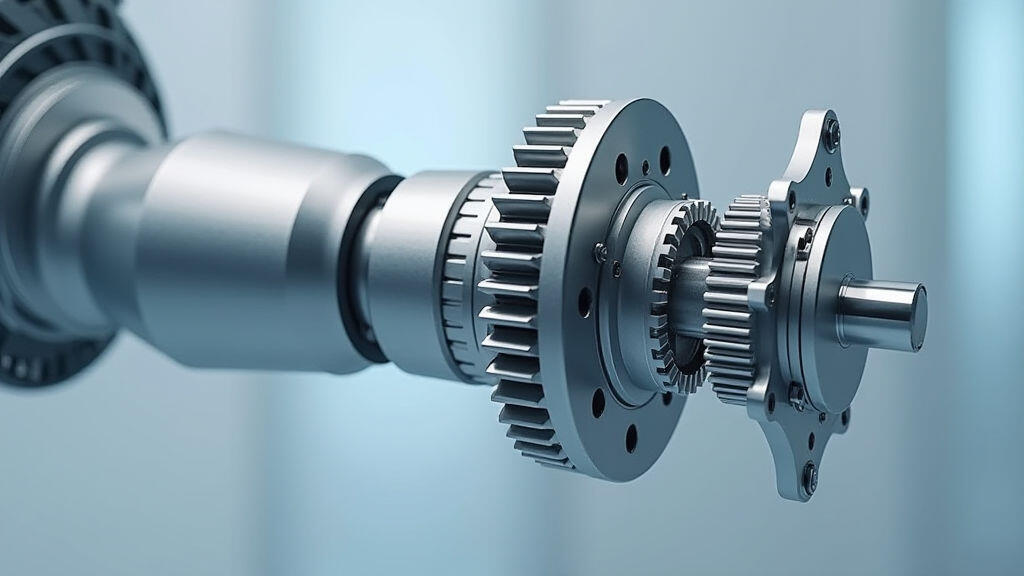

Image 1: Illustration of a planetary gear motor in a robotic surgical arm

Selecting the Right Gear Motor: A Step‑by‑Step Process

Image 2: Diagram of gear ratio calculation for a medical device application

Key Performance Metrics for Gear Motors in Medical Devices

| Metric | Why It Matters | Target Values (typical) | |--------|----------------|------------------------| | Torque Density | Higher torque per volume enables miniaturization | > 10 N·m/L | | Backdrivable vs. Non‑backdrivable | Safety: non‑backdrivable prevents accidental motion | Worm gears typically non‑backdrivable | | Efficiency | Energy savings, sustained operation | > 85 % at operating loads | | Temperature Rise | Prevent overheating of electronics | < 30 °C rise under load | | Vibration & Noise | Patient comfort, clinical environment | < 40 dB in frequency band 200–1200 Hz |

Installation & Maintenance Best Practices

Mounting: Use vibration‑isolated brackets to reduce mechanical stress on gear teeth.

Lubrication: Apply medical‑grade synthetic lubricants; schedule periodic checks every 1,000 operation hours.

Monitoring: Integrate torque sensors and temperature probes in the control system for real‑time diagnostics.

Redundancy: For critical life‑support systems, install dual motor stages to allow fail‑over during maintenance.

Case Study: Upgrading an Automated Dialysis Unit

A dialysis clinic retrofitted its 50‑unit automated dialysate pump set. The original brushed DC motors were reaching their limits after 20,000 cycles, leading to frequent downtime. Engineers replaced them with BLDC planetary gear motors (3:1 reduction) rated at 5 Nm torque and 500 RPM. Results after 6 months:

This upgrade demonstrated how careful gear motor selection can extend equipment life while enhancing clinical outcomes.

Future Trends in Gear Motor Technology

These developments point toward gear motors that not only deliver motion but also communicate health status—an invaluable feature for critical patient care devices.

Conclusion

Gear motors are the unsung heroes of medical automation. By translating electronic signals into precise, reliable mechanical motion, they enable the sophistication of modern surgical robots, drug delivery systems, and imaging devices. Selecting the right motor requires a systematic approach—defining motion needs, matching motor-base types, choosing the correct gear ratio and type, and ensuring compliance with stringent medical standards.

The 2024 International Medical Technology Expo highlighted the growing demand for compact, high‑efficiency motors that can withstand the rigorous cycles of life‑support equipment. As AI, advanced materials, and wireless technologies merge with traditional gear design, the potential for even smarter, safer, and more energy‑efficient medical devices expands dramatically.

Investing in the right gear motor today means tomorrow’s clinics will benefit from smoother operation, reduced maintenance, and, ultimately, better patient outcomes.

Leave A Reply

Your email address will not be published. Required fiels are marked